We’d like to announce the latest update to the Shapeoko product line, the Shapeoko 5 Pro.

The Shapeoko 5 Pro is a massive upgrade in capability and performance. It is meant to be the last CNC router you’ll buy, not a stepping stone to something better. It is the culmination of 11 years of experience and feedback from the community.

The upgrades did not come cheap but we made every effort to reduce the parts count as much as possible and put all of the cost into items that make the machine better and add value. It’s not an exaggeration to say that the six of us that worked on the design spent hours discussing, frequently arguing about, every component of this machine. If we tried to make this machine even a few years ago, it would have been a lesser machine. We’ve learned a lot about what works and what doesn’t, and we’ve got vendors and in-house capabilities now that we’ve never had before.

We’re ultimately a group of CNC nerds, not marketing people. We have a hard time with the hyperbolic statements made by competitors, so much so that we tend to undersell our own machines when we release them. I say that just to frame this statement, and let you know that we’re confident that we’re not being hyperbolic:

There’s no other CNC router on the market that can do what Shapeoko 5 Pro can do at the same price point. Some machines can’t touch the Shapeoko 5 Pro, even at twice the price.

With that said, let’s move on to the details.

What’s New

![Shapeoko 4 vs 5]()

So, What’s new in Shapeoko 5 Pro? Everything. There’s nothing shared with the Shapeoko 3, Shapeoko 4, or Shapeoko Pro. We’ve got a new frame, new extrusions, new motion system, new electronics, new motors, new GRBL, new everything.

We considered every problem we were aware of, every user request (OK, almost every user request), and every recurring support question. We implemented every request and every fix that we could reasonably accommodate. We want this to be the flagship Shapeoko for a long time, so it has to be the best machine possible.

New, Larger Sizes

![sheet passthrough]()

If I had to tell you why the Shapeoko 3, 4, and Pro are the sizes they are, I’m not sure I could. I’m sure we had a good reason at the time but users now want bigger and bigger machines, especially sizes that map to standard plywood dimensions. Shapeoko 5 Pro is available in three new sizes:

- Shapeoko 5 Pro 4x4 - 48” x 48”

- Shapeoko 5 Pro 4x2 - 48” x 24”

- Shapeoko 5 Pro 2x2 - 24” x 24”

Z-travel on all machines is now 6” (155mm) and clearance under the gantry is 4”.

The new Hybrid Table is pass-through capable, so you can slide a 4x8’ sheet of plywood through the machine on either the 4x2’ or the 4x4’ sizes.

These larger sizes open up a new world of opportunities for you:

- Make large items, like furniture and cabinets.

- Nest more parts on a sheet.

- Index really big parts through the machine.

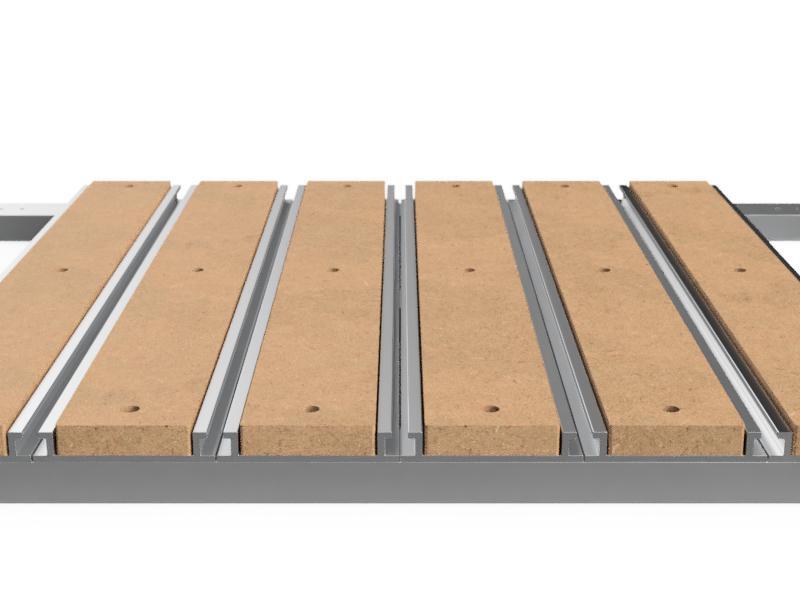

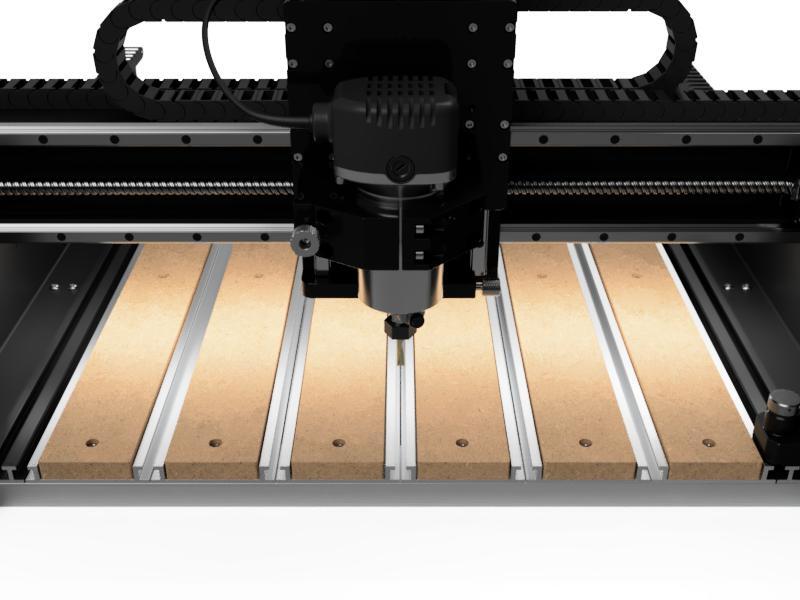

Hybrid Table

![Hybrid Table]()

I’ve said it again and again, the Hybrid Table was my favorite addition to the Shapeoko 4, Pro, and HDM. It’s a phenomenal workholding system that also lets you create a completely flat surface for precise cuts. The Hybrid Table also fully supports the Y-axis for greater rigidity.

To support the new machine sizes, we made a couple of tweaks to make the Hybrid Table even better:

The table spacing and dimensions have been tweaked so that all of the MDF is now completely machinable by the cutter. That means that you can surface the Hybrid Table without the machine leaving remnants that would make it impossible for an oversized sheet of wood to sit flat on the table.

The table T-slot spacing is now 4.04”, instead of 100mm.

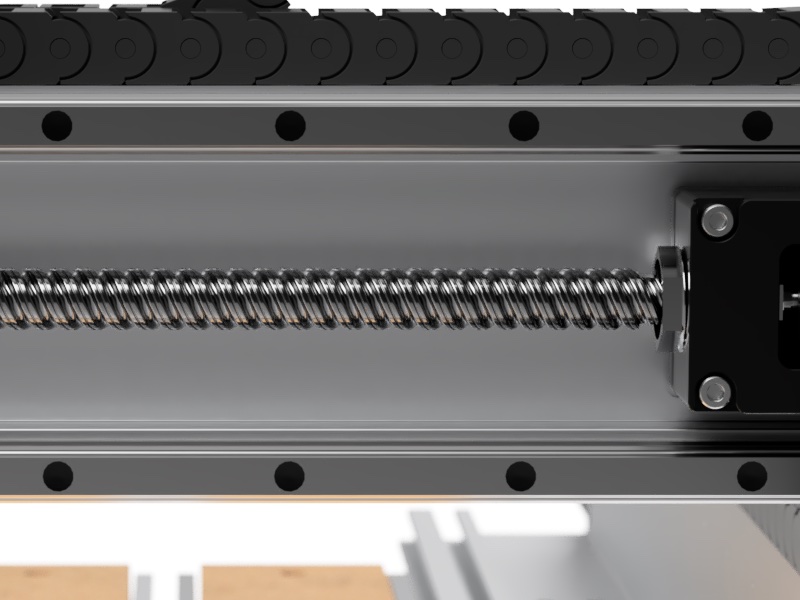

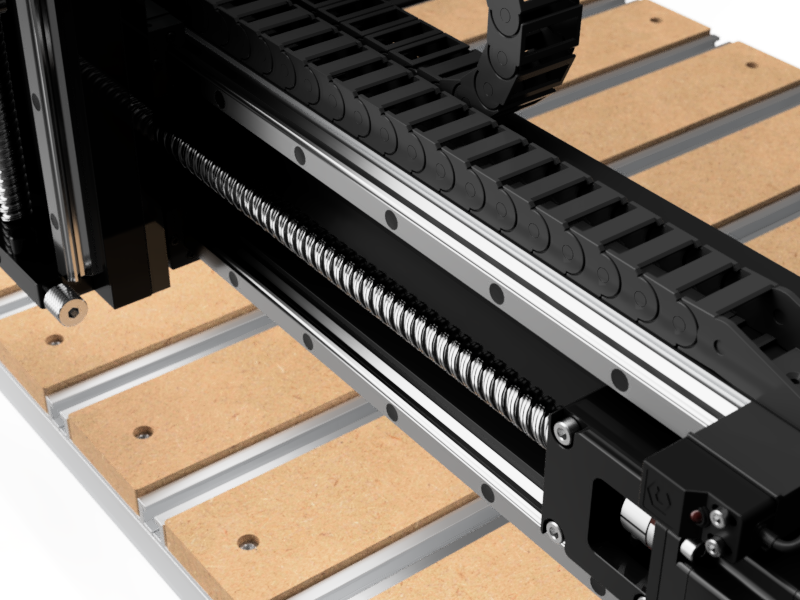

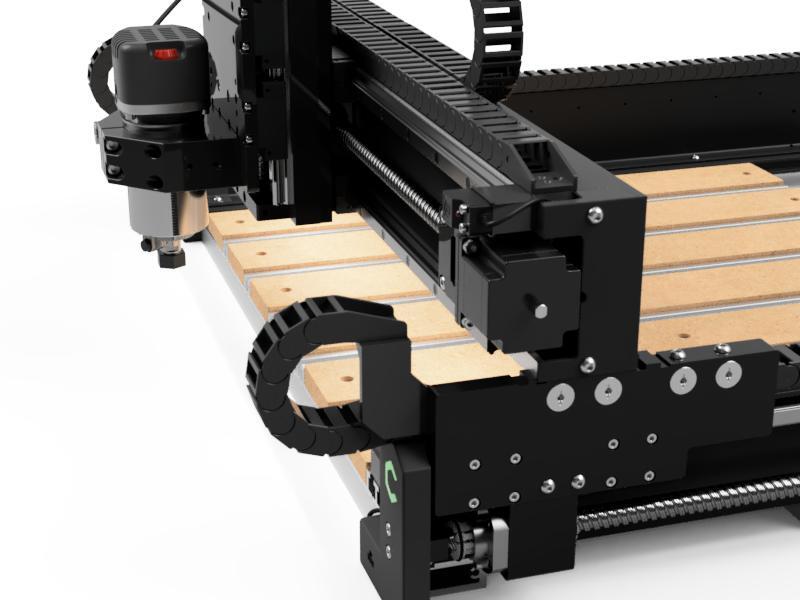

Belts Are Out, Ballscrews Are In

![Ballscrews]()

We remain big fans of belts, for reasons that we’ve enumerated many times before, but the Internet has spoken and it doesn’t like them. We give up. Shapeoko 5 Pro uses ballscrews on every axis.

A couple of years ago, we would have had more reservations about ballscrews. We’ve shipped a lot of them in the Shapeoko HDM, and we’re confident that our vendor is reliable and that the ballscews are high quality.

Now, it wouldn’t be “The Carbide Way” if we made this easy, so we spent the time to make those ballscrews exactly what we wanted. For the X and Y, we got 16mm diameter screws with a 20mm pitch. We did this to ensure that we didn’t lose the travel speeds that we had with belts. We also made sure the X and Y ballscews have our custom wipers to keep the dust and debris out of the way.

Speaking of dust, we arranged the Y ballscrews so that they are shielded from the working area of the machine by the Y extrusions.

Dust is the mortal enemy of ballscews so we think the wipers and ballscrew positions are critical.

We also had a custom motor coupler made. This may seem like a trivial thing but we’ve found it to be deceptively important. On the Shapeoko HDM, we found a couple of cases where the coupler came a little loose and the ballscrew slipped. In our testing, this new coupler is a big improvement and it should eliminate one source of trouble.

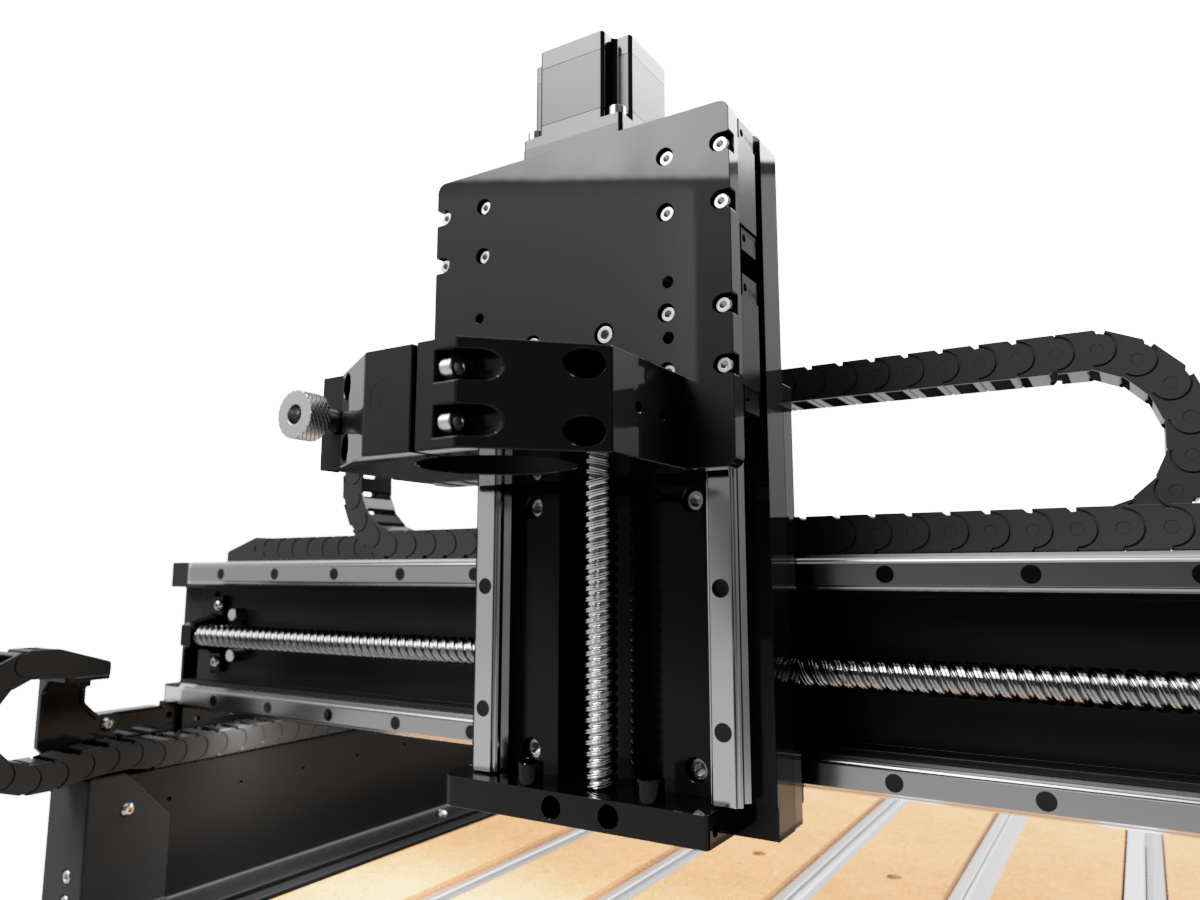

HDZ Included

![HDZ]()

Speaking of ballscrews, the Shapeoko 5 Pro also includes the HDZ Z-axis unit, which uses a ballscrew and HG-15 Linear rails. The HDZ used here is largely the same Z-axis that we use in the Shapeoko HDM (changed slightly to accommodate different mounting holes).

The HDZ is strong enough to use with any spindle, from a trim router to a 65mm or 80mm VFD spindle. Using the Z-axis from the Shapeoko HDM means that you can also upgrade to the Sweepy Pro if you prefer a fixed dust boot.

HG-15 Linear Rails

![Linear Rails]()

For the X and Y axis, we’ve upgraded to HG-15 linear rails. These are the same rails we’ve been using on the HDM, and they’re a big upgrade over the V-wheels on the Shapeoko 4 and the MGN rails used on the Shapeoko Pro.

HG-15 rails would be completely at home on a much bigger and much heavier machine but you won’t mind having them on this machine- they’ve very rigid, very smooth, and well-sealed. They’ve been trouble-free on the Shapeoko HDM.

Fully-Machined Extrusions

For the X and Y axis, we have two all-new extrusions that are machined in-house to mount both the ballscrew and the rails. We do not use T-slots or other tricks to avoid the work of putting an extrusion in a machining center to make sure the rails can be mounted and located as accurately as possible.

We’ve been doing custom extrusions for a long time and we’d like to think each one is better than the last one. These extrusions are no exception. As, always, they’re rigid and overbuilt but we’ve added a lot of little features in them to allow us to remove extra parts that cost money but added no real value to you.

Dual Y-homing

The Shapeoko 5 Pro now includes dual Y homing so that both sides of the machine are homed independently. This was kind of a toss-up, we didn’t have strong opinions on it, but people have mentioned wanting it before and we were able to include it without adding significant cost.

To make dual homing worthwhile, you must make at least one homing switch adjustable so it’s possible to square the machine up easier. We’ve done that with the Shapeoko 5 Pro by developing a new limit switch mount that includes a way to micro-adjust the location of the limit switch on the left side of the machine, and then lock it down to prevent it from changing position over time.

Shapeoko 5 Pro continues to use the same inductive limit switches that are used on the Shapeoko 4 and Pro.

Gantry Shift for Joinery

![Gantry Shift]()

Some users like the machining area to come off the front of the machine to make edge machining, to make tenons or dovetails for example, easier. We’ve added a gantry shift option to the Shapeoko 5 Pro that allows you to move the gantry forward by 3.2”. Users that want a little overhang can get it, while the majority of users get to keep the machining area directly over the table.

New Spindle Mount

The Shapeoko 5 Pro uses a new spindle mount that includes an accessory clamp to make it easy to add and remove accessories. We’ve got a number of these accessories planned, so stay tuned for more information.

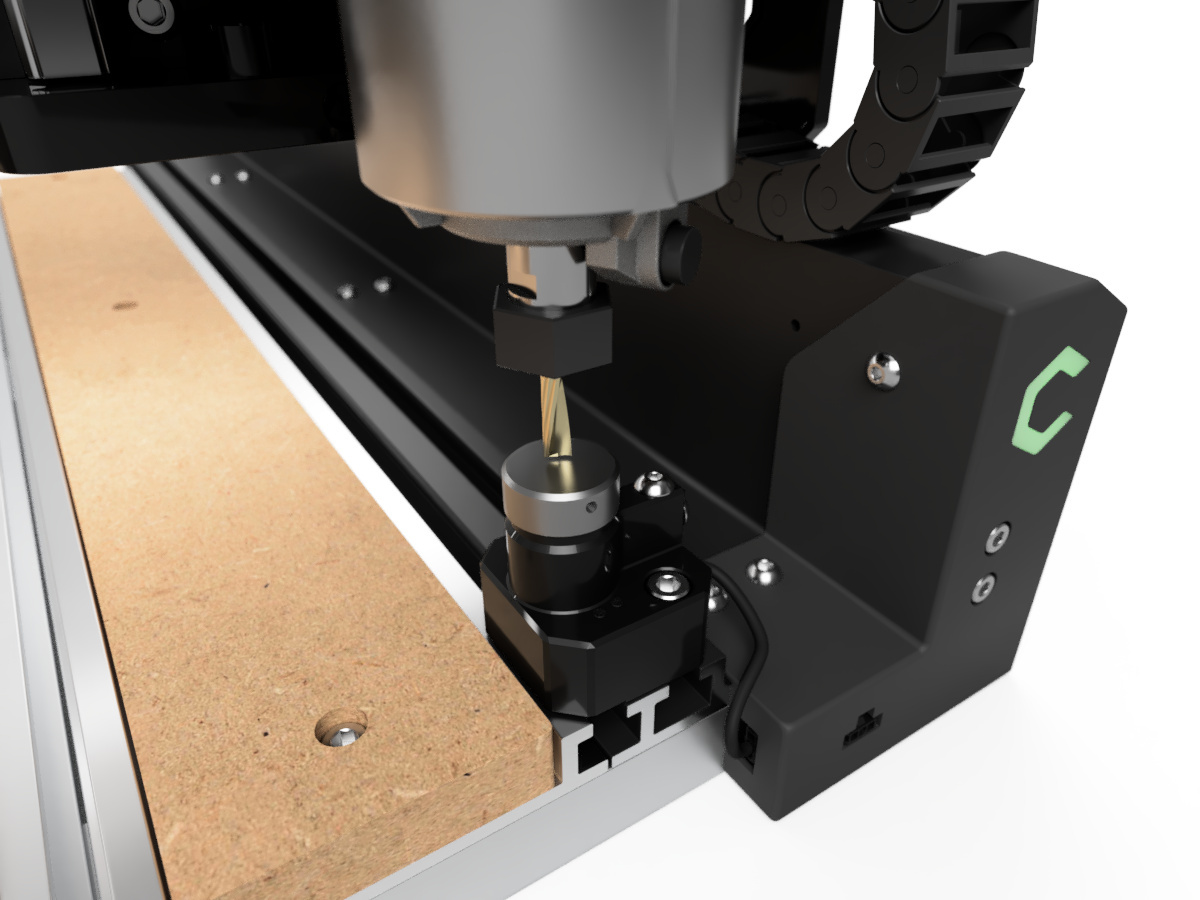

BitSetter

![BitSetter]()

Shapeoko 5 Pro includes an all-new BitSetter to make tool changes easier. Here’s what we changed:

- BitSetter now uses a high-quality mechanical switch to reduce the size of the BitSetter to leave more machining area for your projects.

- It’s got a larger-diameter top to make it easier to use with larger bits.

- The top is replaceable without having to remove the BitSetter from the machine or take it apart.

- It’s got better LED indicators to check that it’s plugged in and working correctly.

We also added some internal plumbing to make an air blast possible, which will be useful for some users. The stem and fittings will be a separate low-cost purchase so that nobody will be confused that they need compressed air for their machine.

We were able to fit the BitSetter into a location that still allows you to fit a full 48” wide piece of material into the machine (for the 4x2’ and 4x4’ machines).

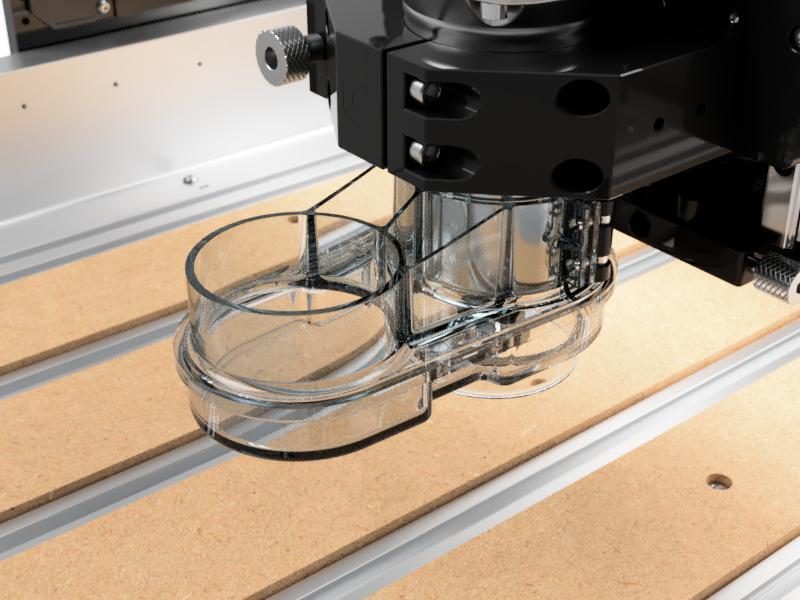

Dust Collection

![Dust Collection]()

Shapeoko 5 Pro still ships with Sweepy V2, but it’s now also compatible with the Sweepy Pro, if you prefer a fixed dust boot. We’d still recommend Sweepy for most folks, but it’s good to have options.

There are also now dedicated grounding points on the machine for dust collection to eliminate the potential for ESD-related problems due to the vacuum and hoses.

Power Pendant

![Power Pendant]()

In the Shapeoko Pro, we mounted the power button on the front of the machine, and a lot of people liked that. The one problem is that many users put their machines in a full enclosure so they had to open the door to kill power. Shapeoko 5 Pro includes a power pendant that can be mounted on the outside of the machine enclosure, so you can kill power without opening the door. The power pendant also includes a feedhold button if you’d like to pause the program mid-job.

The Power Pendant is on a one-meter tether so you can mount it wherever you’d like.

New Electronics

Shapeoko 5 Pro includes redesigned electronics taking everything we’ve learned from the very first Shapeoko 3 to the Shapeoko HDM.

- The electronics are now on a one-meter tether so you can mount the electronics outside your enclosure.

- The power supply is now built into the electronics box, so there’s no external power supply to deal with.

- We’ve optically isolated the USB and all inputs and outputs to prevent ESD problems.

- We’ve got expansion ports for future features. (Which should be pretty cool)

- There are only two connectors for the whole machine now, one for the limit switches and one for all of the motors, making it more difficult to wire a machine incorrectly. (We’ve all done it, so we know how easy it is to make a mistake)

The new electronics box is a sealed unit that you never have to open.

We still use drag chains for all of the wiring. There’s no good way to keep the wiring from flopping around on a machine this size without them.

Lights Under the Gantry

![Lights]()

Shapeoko 5 Pro includes LED lighting under the gantry. Jorge pushed hard for this on the HDM and, after you’ve seen it, you can’t go back. I hate to admit it, but Jorge was right.

The lighting will be especially useful for people that put their machines into an enclosure that blocks the shop lighting.

BitZero Plug

This is another little, quality of life upgrade- there’s now a plug on the front of the machine for BitZero so you can unplug it to get it out of the way more easily.

We also added an illuminated Carbide logo since we already had a PCB in the front of the machine. Winston is proud of this, be sure and tell him you like it.

Assembly and Setup

Shapeoko 5 Pro ships more ready-to-run than ever before. The X and Y units are preassembled and pretested in our shop so they’re almost ready to go.

We’ve eliminated a lot of the custom hardware we used before and moved to hardware that is more familiar to everyone. This doesn’t make the machine inherently better, but we think it will make the machine easier to assemble and easier to maintain.

We’ll be curious to get feedback from real users but we estimate the assembly will take half the time of the Shapeoko 4 or Shapeoko Pro. You can be cutting on day one.

Replacement Parts

By the time we ship, we should have every part that could need to be replaced available online. All of those parts ship with a QR code on them that links directly to a product page where you can buy a replacement. We hope this will take us out of the position of being a bottleneck for support.

What’s (Still) Included?

While the machine has changed in a big way, the experience hasn’t. We still ship the most complete experience you can get in a CNC router:

How Good is It?

I’m an engineer so I like questions that have definitive answers, and that makes “How good?” a tough one for me. Instead, I’ll share an anecdote:

We needed to make room in the shop for the new 4x4 and we had an HDM prototype collecting dust so I went to Winston and asked him if he’d like to take it home.

He thought for a second and replied, “Honestly, I’d rather wait for a Shapeoko 5.” If you know Winston, that’s quite an endorsement. Personally, I wouldn’t call it “better” than the HDM, but it’s pretty close when you add our VFD spindle.

What Happens to Shapeoko 4, Shapeoko Pro, and Shapeoko HDM?

If you own a Shapeoko 4 or Pro, nothing changes. They’ll still be fully supported and parts will remain available. Software updates will continue to include support for the Shapeoko 3, 4, and Pro machines.

Can a previous Shapeoko be upgraded to the 5 Pro? Unfortunately, they cannot. The Shapeoko 5 Pro is a completely new machine and I don’t think there’s a single shared component between the 5 and prior machines.

We will probably eliminate either the 4 or the Pro from our store to reduce confusion but we’ll continue to have a lower-cost option available for people who don’t want to commit to the price of the Shapeoko 5 Pro.

We do plan on offering the new electronics as an upgrade for the Shapeoko 3, 4, and Pro. We’ll need to get enough inventory and then work out the wiring adapters before we’re ready for that.

The Shapeoko HDM will continue to live on. It’s fundamentally a more powerful machine, and it ships ready to run, so we think they’re appropriate for different audiences. We do think the Shapeoko 5 Pro will be great option for international customers that have wanted to buy an HDM, but haven’t been able to get one.

Will there be a Shapeoko 5 non-Pro? No, there won’t. We’ll probably use the term “Shapeoko 5” and “Shapeoko 5 Pro” interchangeably.

Will we make a 4x8 machine? It’s not on the drawing board right now.

How Will Ordering Work?

We’ll be opening up preorders in the next week or two, and we’ll be updating the store daily with the expected lead times for shipping. Here are a few things to know:

- Right now, we’re hoping that the first machines will ship a few weeks after orders open up.

- We’ll give our best estimate for shipping, but anything can happen. We’ll do our best to keep you updated on the expected shipping date.

- If you decided to change your mind, you can cancel your order at any time up to the day we ship. We’ll refund your money and you’ll be free to order again whenever it’s convenient for you.

- We don’t have a way to do partial payment for preorders. Shopify (our e-commerce platform) just added this feature but it depends on third-party apps, and we don’t feel comfortable using an untested feature/app on a big launch.

- Once you order, we’ll give you an order batch number and periodically email you the expected shipping date of each batch. Dates may change, but we’ll do our best to keep you updated.

- We have a lot of parts on hand to build the Shapeoko 5 Pro, and more parts and materials are on the way. If delays happen, they will likely be due to production growing pains, or shipping delays for the next rounds of production materials.

- Now that everything is public, look for more information to trickle into the product page on the store and the documents at https://my.carbide3d.com.

Why Now?

Finally, the evergreen question, “Why did you announce this today and not months ago?” Because we’re finally sure that the risk of delay is acceptably low. We’d hoped to be shipping these six weeks ago but parts and materials were delayed. For all we knew, the parts could have been delayed another month or two so today is the day.

That said, the risk of delay is not zero, so the best we can say is that we’ll try to keep everyone up to date as we get closer to shipping.

Conclusion

We’re excited to get these machines out to you, we know you’ll love them. We’ll be here to answer any questions you have in the meantime.

We’ll get some videos posted in the next week or so to show a Shapeoko 5 Pro in action.

Until then, check out the Shapeoko 5 Pro here: https://shop.carbide3d.com/products/shapeoko5

Now that Shapeoko 5 Pro is public, the clock is ticking for us and we’ll be at an all-out sprint. We’ve got work to do!